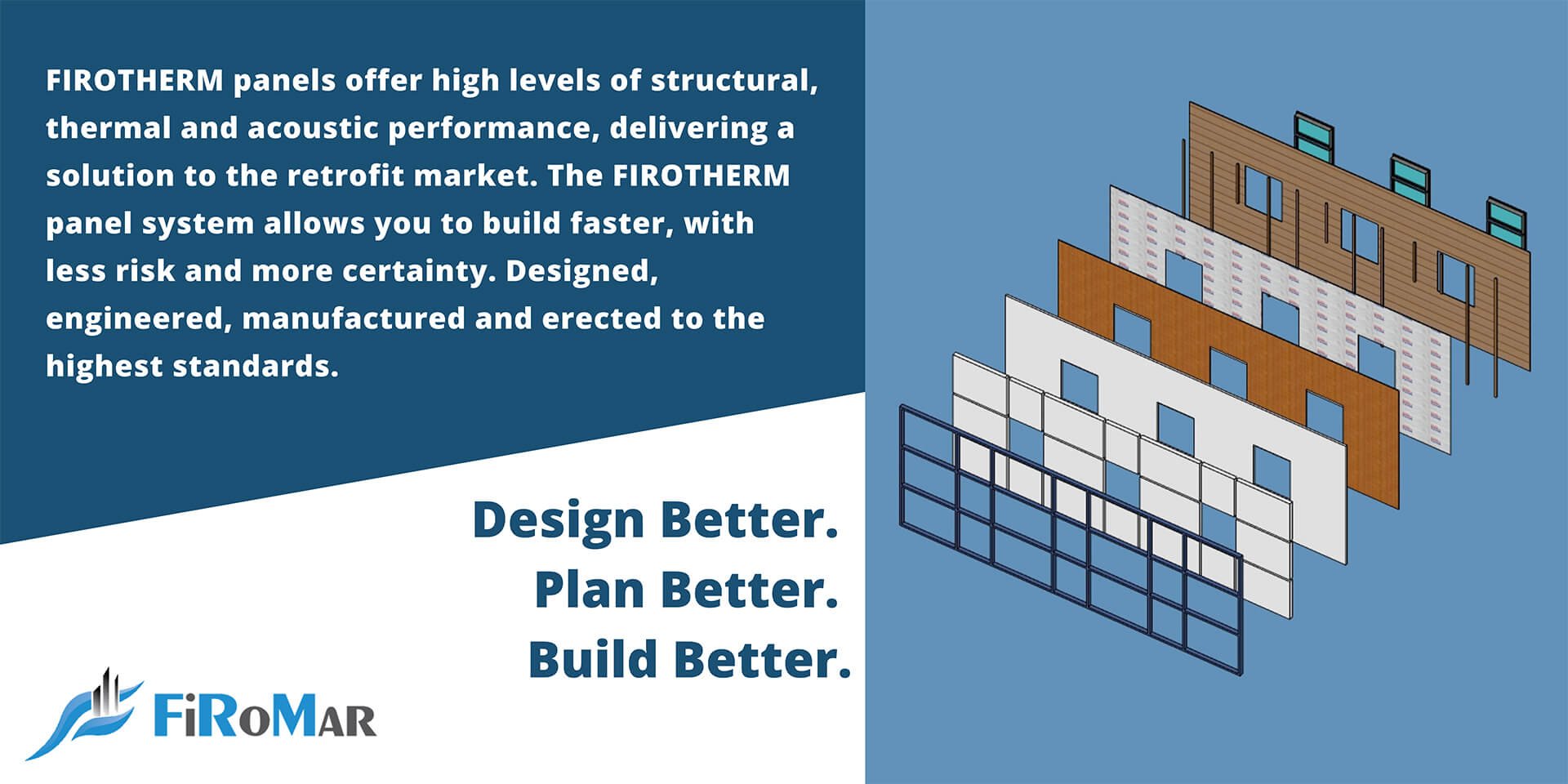

Firomar is a pioneer of lightweight pre-insulated exterior envelope systems, providing a panelized system solution in a market where one doesn’t currently exist. We provide structurally sound, energy-efficient, lightweight expanded polystyrene / graphite polystyrene (EPS/GPS) panels (FIROTHERM) that don’t degrade with time. We are unique in North America, with the largest EPS/GPS mold in the world. Firomar’s patent pending technology provides additional insulation, meanwhile eliminating additional steel framing.

Firomar is a pioneer of lightweight pre-insulated exterior envelope systems, providing a panelized building envelope system solution. Firomar’s panels are structurally sound, energy-efficient, lightweight expanded polystyrene / graphite polystyrene (EPS/GPS) panels (FIROTHERM) that don’t degrade with time. Firotherm panels offer a unique energy savings solution in North America, with the largest EPS/GPS mold in the world. Firomar’s panel technology integrates structure, insulation, and cladding support in a single factory process, which is unmatched in thermal and structural efficiency.

Deep energy retrofits throughout the US will not be possible without Firomar’s building envelope solution. Firomar’s patent-pending technology guarantees that FIROTHERM panels surpass any competing panel in energy efficiency and structure. FIROTHERM is able to achieve R-Values while providing a lightweight panel, which is necessary when retrofitting. FIROTHERM panels are pre-engineered and manufactured in a quality-controlled environment to exact standards, delivered for installation and achieve an energy efficient retrofit solution. No other panel manufacturer on the market has this technology.

To ensure an optimized building envelope, Firomar provides Survey-Design-Model (SDM) system, which develops a digital representation of physical characteristics of a building. Using SDM, Firomar manages all stages of the process, from concept, to design, to manufacturing and then installation. SDM takes final assembly into account as we model our panels, ensuring they are tailored to the unique aspects of each building. Firomar’s SDM system puts all the pieces together virtually ensuring successful onsite integration.

Survey: Firomar has developed an automatic point cloud processing method, which we use during the Survey stage. The Survey process involves field laser-scanning, which detects large volumes of 3D laser scanning data of building facades, and then converts the raw point cloud into CAD geometries.

Design: After the site is surveyed, the information then gets moved into our BIM software programs. The files we get off the lasers are then manipulated to create images that can be layered with assemblies such as windows, doors, and walls. This allows for design integration of mechanical, electrical, and plumbing in 3D.

Model: The Model stage of the SDM process takes us from Design and into concept. At this stage, we put together the finishes, connections, and any other final touches that will be attributed to the panels. This ensures that the panels will be ready for immediate installation once they arrive on-site.